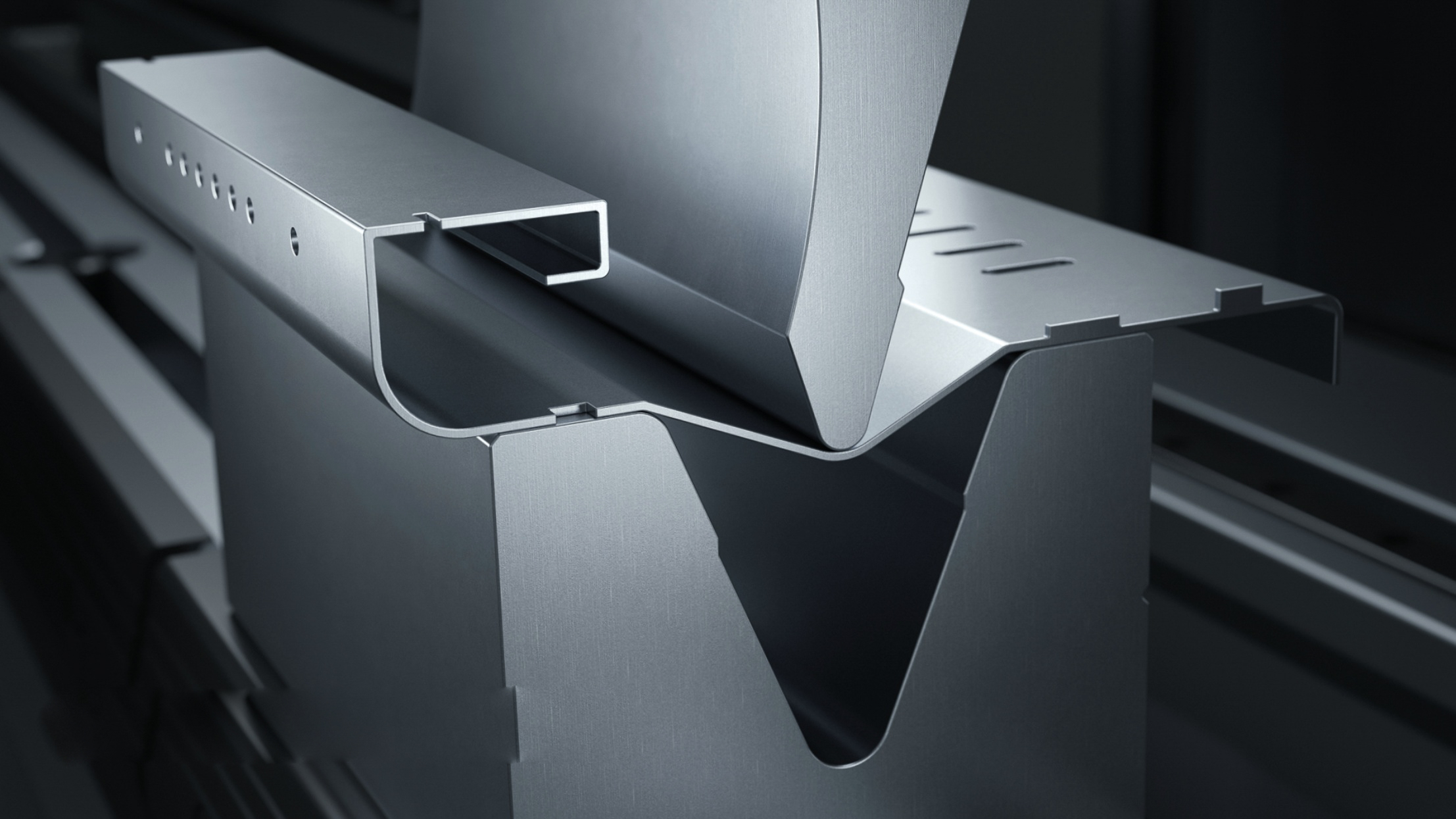

Technology

Complete processing of sheet metal, profiles, and tubes, including surface finishing, on precision CNC machines.

Contact usComplete services

A wide range of metal fabrication services, including laser cutting, bending, welding, and painting, using state-of-the-art CNC technologies.

Precision manufacturing

Thanks to modern TRUMPF, BLM, CODATTO, and GASPARINI machines, we achieve maximum precision in metal cutting and forming.

Focus on quality

We carefully monitor customer satisfaction, select the best material suppliers, and regularly train our employees.

Continuous improvement

We analyze production processes and implement corrective measures to ensure our products meet the highest quality standards.

Laser cutting

Laser cutting is a key technology of kovo VESUV. It is a highly advanced process that enables the cutting of precise components from various metal materials (e.g. sheets, tubes, and profiles), which are then further processed on CNC bending machines, welded, or fitted with fastening elements.

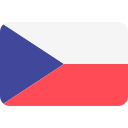

Fiber lasers for profile and tube cutting

At kovo VESUV, we operate the following fiber lasers for profile and tube cutting:

• LT-FIBER EVO fiber laser

• LT-5 fiber laser

Fiber laser LT-

FIBER EVO

The latest equipment at Kovo VESUV includes fiber laser machines in which the laser beam is delivered to the cutting head via an optical fiber. The outstanding LT FIBER EVO machine is a fully automated center that enables cutting of profiles or tubes with diameters ranging from 12 mm to 152 mm.

No manual adjustment is required when changing the profile type. Switching to a different production setup is seamless and time-efficient, allowing maximum utilization of the machine’s productivity.

Fiber laser LT-FIBER EVO

Fiber laser LT-5

FIBER LASER LT-5 is an automated laser machine designed for cutting tubes with diameters from 15 mm to 70 mm and square profiles up to 50 × 50 mm. It is characterized by first-class product quality and high speed.

Fiber laser LT-5

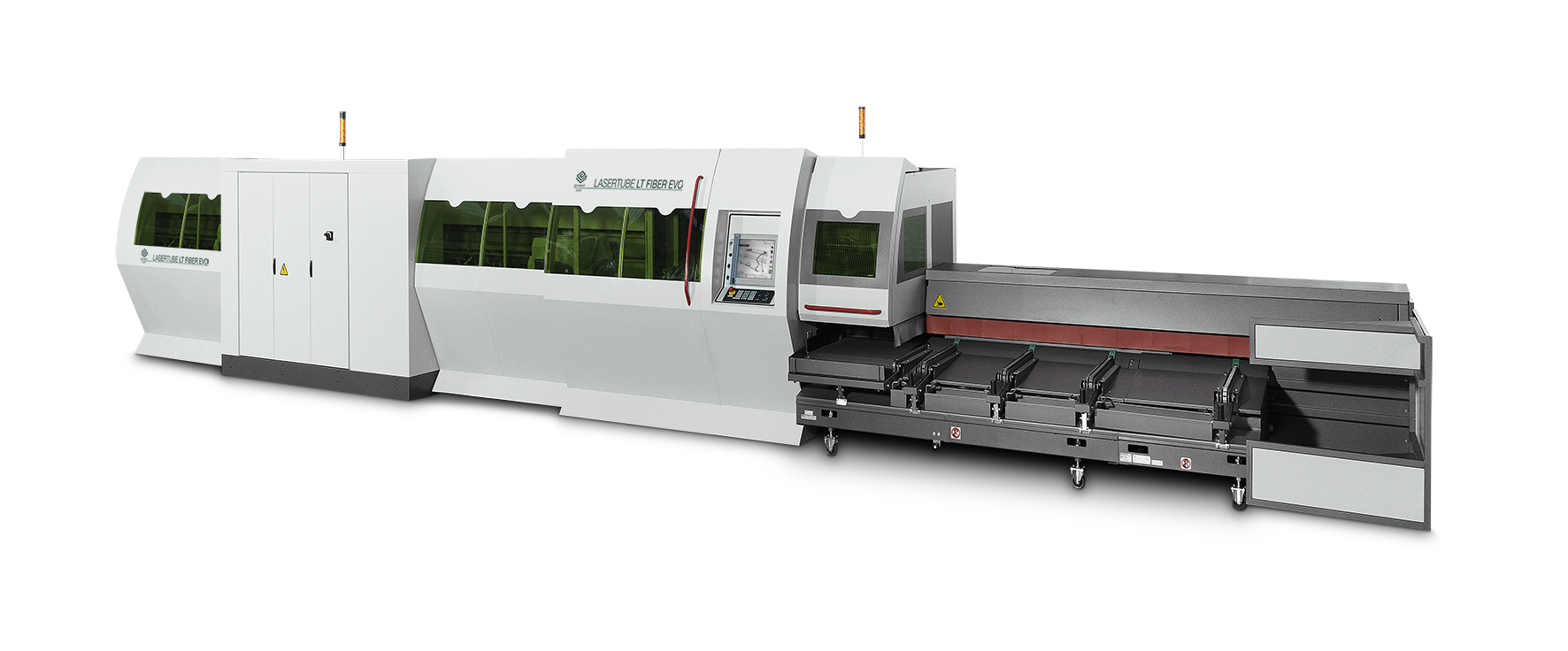

Laser machines for sheet metal cutting

Our company is equipped with highly powerful laser machines:

Trumpf TruLaser 3030 laser machine

BLM LS7 laser machine

Both machines are designed for cutting sheet metal made from various materials – steel, stainless steel, aluminum, copper, and others. The maximum sheet size processed is 3000 × 1500 mm. Depending on the material type, sheet thickness can exceed 15 mm. The appropriate use of cutting gas prevents oxidation of the cut edge, ensuring excellent dimensional accuracy and minimal thermal impact on the base material.

Fiber laser LT-5

Fiber laser LT-5

Comprehensive metal fabrication services

- kovo VESUV provides a wide range of services in the field of modern metal fabrication. Thanks to state-of-the-art technological facilities, we specialize in laser cutting of sheets, profiles, and tubes using the latest CNC machines from TRUMPF and BLM.

- Owing to our broad range of manufacturing processes, we are able to respond flexibly to individual customer requirements and deliver products with maximum precision and quality.

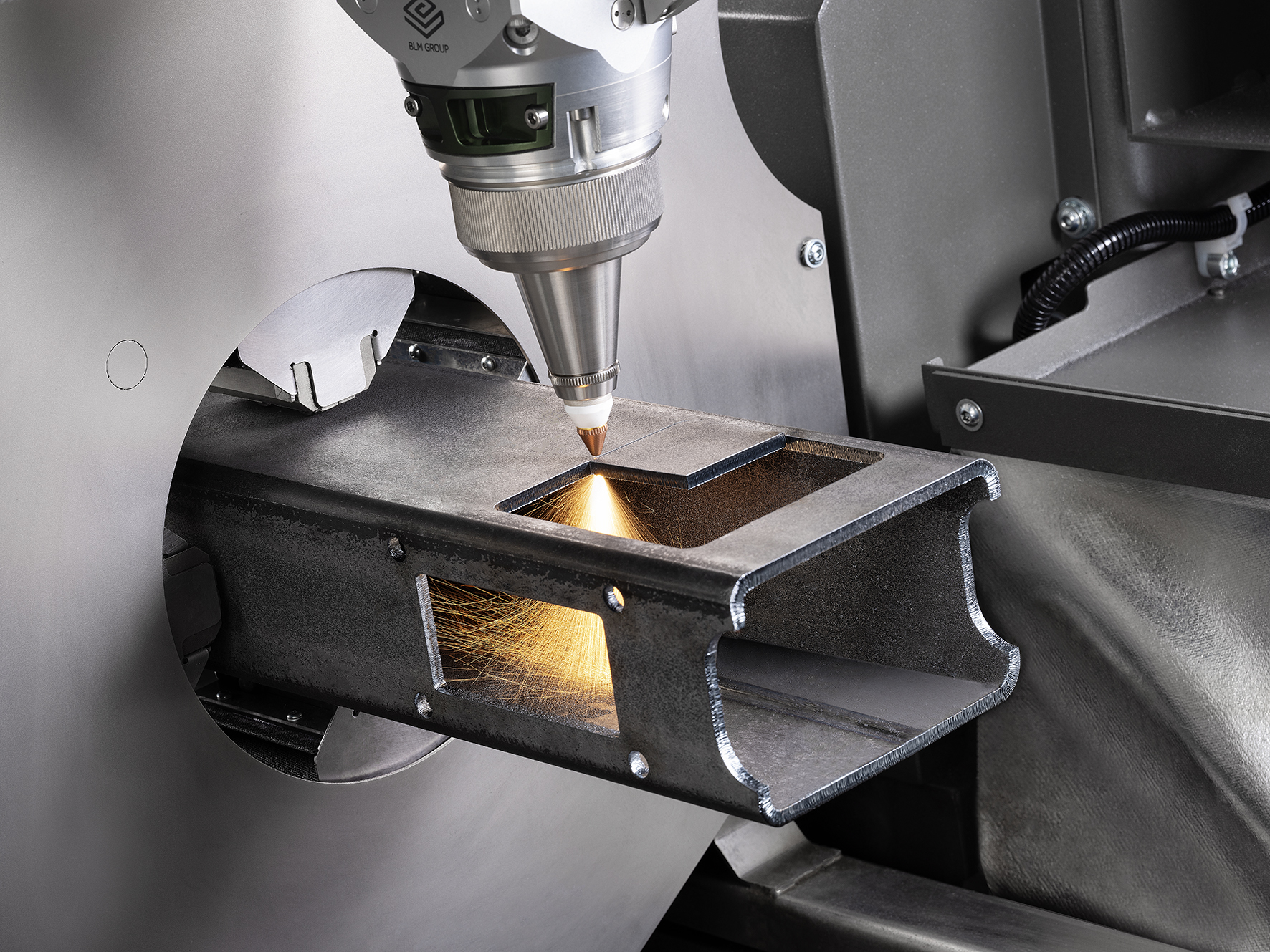

CNC punching

Another machine at Kovo VESUV is a CNC punching machine designed for precise sheet metal processing.

- TruPunch 1000

This machine is capable of punching/perforating metal sheets with thicknesses ranging from 0.6 to 4.0 mm, with maximum sheet dimensions of 2500 × 1250 mm. The machine is based on a wide open frame design, featuring a movable table and tool magazines.

The resulting products can have various shapes according to customer requirements and are intended for further processing, such as bending, welding, etc.

In addition to punching/perforating various holes and edges,

the TruPunch 1000 can perform further forming operations, including multiple-hole punching, forming ventilation louvers, tapping, small bends, and more. All these operations depend on the tools used, which we design in-house and subsequently have manufactured by a specialized supplier.

CNC press brake bending

For bending, we use the following machines:

- Semi-automatic CNC bending machine EVA 3122 (more here)

- CNC press brake SAFAN DARLEY e-BRAKE B (more here)

- CNC press brake GASPARINI XP 50/2000 (more here)

- CNC press brake GASPARINI PBS 165/3000 (more here)

These machines provide highly precise bends. A special camera system captures the actual bending process of the product, allowing the operator to adjust the tool pressure so that the resulting bend is accurate. The machines have very high capacity. These press brakes allow bending of sheet metal up to a maximum length of 3,000 mm with a bending force of 1,050 kN.

Comprehensive metal fabrication services

We provide precise sheet metal bending on CNC press brakes by CODATTO and GASPARINI, as well as bending of tubes and profiles on the BLM E-Turn40 machine.

Comprehensive metal fabrication services

kovo VESUV provides a wide range of services in the field of modern metal fabrication. Thanks to state-of-the-art technological facilities, we specialize in laser cutting of sheets, profiles, and tubes using the latest CNC machines from TRUMPF and BLM. Thanks to our broad range of production processes, we are able to respond flexibly to individual customer requirements and deliver products with maximum precision and quality.

Comprehensive metal fabrication services

kovo VESUV provides a wide range of services in the field of modern metal fabrication. Thanks to state-of-the-art technological facilities, we specialize in laser cutting of sheets, profiles, and tubes using the latest CNC machines from TRUMPF and BLM. Thanks to our broad range of production processes, we are able to respond flexibly to individual customer requirements and deliver products with maximum precision and quality.

Comprehensive metal fabrication services

kovo VESUV provides a wide range of services in the field of modern metal fabrication. Thanks to state-of-the-art technological facilities, we specialize in laser cutting of sheets, profiles, and tubes using the latest CNC machines from TRUMPF and BLM. Thanks to our broad range of production processes, we are able to respond flexibly to individual customer requirements and deliver products with maximum precision and quality.

Tube

bending

At Kovo VESUV, we also operate a tube bending machine:

- BLM E-Turn40 tube bending machine

This machine enables bending of tubes with diameters ranging from a minimum of 4 mm up to 40 mm. The machine is fully electric, without any hydraulic components. This model operates with an automatic bending cycle to both the left and right.

Pressing of special components

Pressing is one of the standard manufacturing operations at Kovo VESUV. We press various components, with our main customers coming from the automotive industry. The process is based on press tools of our own design. After verification on prototypes, we have hardened tools manufactured by a specialized supplier. We operate several types of presses with capacities ranging from 6.3 tons to 63 tons. For production, we use both simple press tools and complex progressive tools.

Pressing of special elements is one of the modern technologies. It enables products to be equipped with fastening elements that ensure quick and easy assembly of individual parts in more complex assemblies. For pressing fastening elements, we use PEM SERTER 3000 and PEM SERTER 4 pressing machines.

Welding and spot welding

We use manual welding using MIG and TIG methods, and we also operate two robotic welding stations equipped with welding robots.

For welding, we use various welding fixtures, which we design and manufacture in-house. This allows us to be highly flexible and to meet our customers’ requirements within very short lead times.

Our welders are certified in accordance with ČSN EN 287-1, and our welding procedure qualifications (WPQR) are approved.

Spot welding – We frequently use spot welding technology. It is suitable for joining sheet metal parts (e.g. welding reinforcements to larger sheet metal surfaces) and is also used for welding special nuts and studs.

Manual welding

Spot welding

Robotic welding

Powder coating

As a final surface finish, we use powder coating technology. Before the powder paint is applied, metal products are degreased in a degreasing chamber and then dried in an oven. The cleaned and degreased products are subsequently coated in painting booths, where the powder paint is applied to their surface and then cured in an oven.

We use various types of RAL and PANTONE colors – smooth and textured, matte, semi-gloss, and gloss.

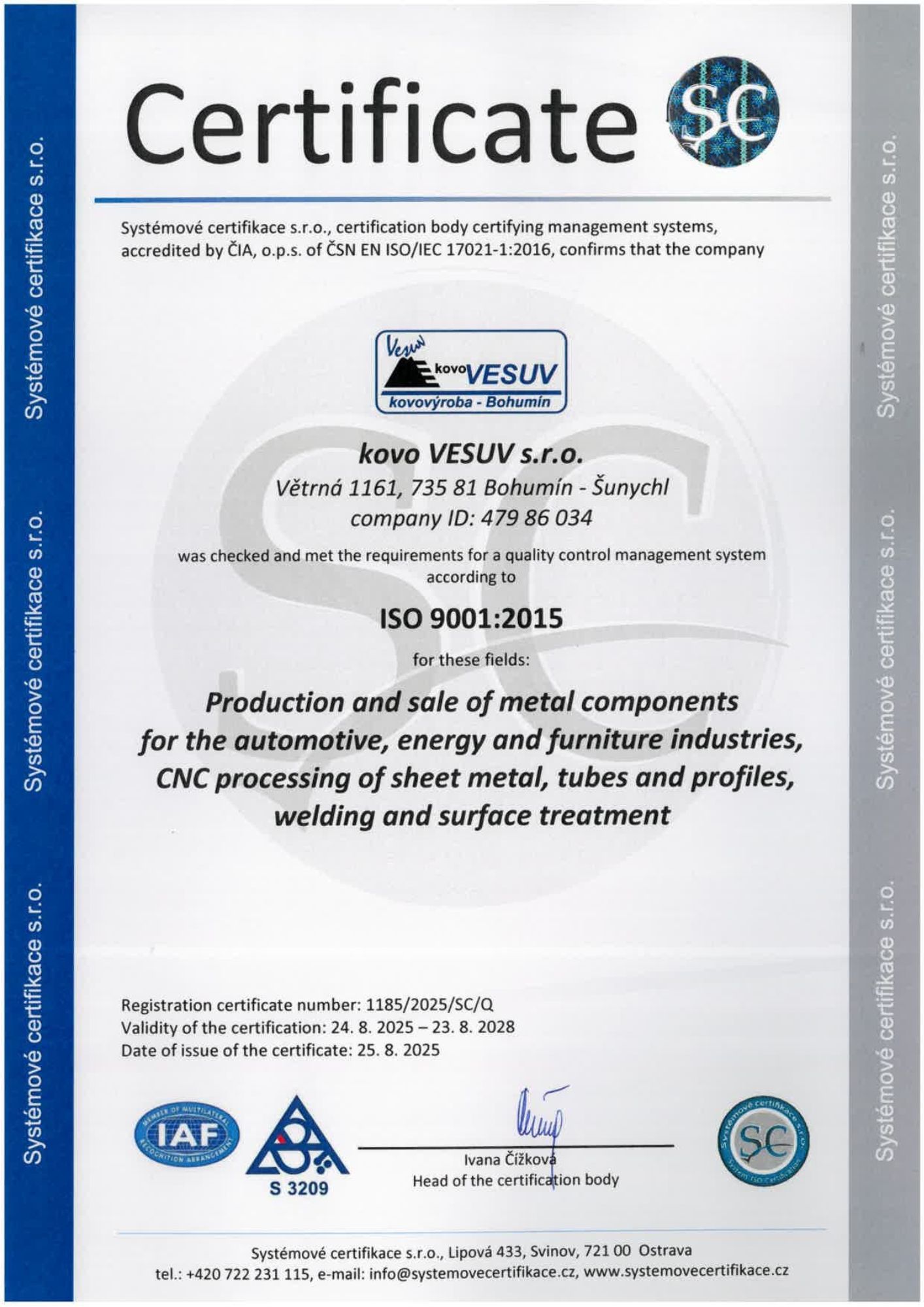

We always place maximum emphasis on the quality of our products and services.

kovo VESUV places strong emphasis on the quality of its products and services. We monitor customer satisfaction, conduct selection procedures for suppliers of sheets, profiles, and coatings, evaluate partner companies, and throughout the year select the best ones.

The company places strong emphasis on the education and personal development of its employees and regularly organizes quality-focused training. Any production discrepancies are analyzed and eliminated through corrective and preventive measures.

Since 2004, Kovo VESUV has implemented a quality management system in accordance with ISO 9001. Each year, the company undergoes an audit conducted by ITI TÜV – TÜV Süddeutschland Group. The quality management system is continuously improved and annually reviewed by trained independent auditors.

Examples from our production facility

If you are interested in working with us, please :

- contact us here: